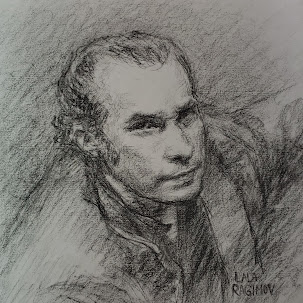

Here are some of my sketches with a small selection of things I learned from the pianist-philosopher.

For me an important lesson from Gould was "the notion of ecstasy as the only proper quest for the artist" that "assumes competence as an inclusive component" as he formulates in an article against music competitions.

You have probably heard about the elusive state of "flow", the holy grail of all creative people. Gould's flow is

special in that he takes it into the realm of trance-like ecstasy, and makes it look so explicitly delicious (watch his Eroica Variations videos on youtube) that you find yourself wanting to try what he's having, enticing you into any kind of creative process of your own.

I am an atheist, and I have often thought of art as an alternative to religion, but only in theory. Gould converted me into art as religion, and with his own example showed the use of art-making as a spiritual practice. And for darker days, one can learn how to get drunk with art as a way to escape from problems or pain directly into paradise.

Confidence in art creates its own truth, and to me Gould is a perfect example of that that both in his art and his career. He joked: "I’ve always been repulsively sure of myself,” but as a result of this assuredness and not caring what the critics said, he dared to create such original and interesting versions of most of the repertoire he played, and make numerous technical and artistic innovations in the media of recording and radio.

Gould's playing style explodes with this confidence: every sound, every musical decision feels like the final statement on the subject, and his are the most definitive silences I have heard. It reminds me of the art of Rubens, who often painted bodies with "wrong" anatomy, that were perfectly convincing and correct artistically because of the dazzling assuredness with which they were painted - confidence can create art more convincing than life itself.

The third important lesson was about being inspired in spite of, and even because of being surrounded by mediocrity. Gould was cultured, well-read and well-travelled, an intellectual and musical genius, and yet he loved grey suburbs, grey people, grey days, and the colour grey.

In his humourous 1966 self-interview he said that he would like to try his hand at being a prisoner because "to be incarcerated would be the perfect test of one's inner mobility and of the strength which would enable one to opt creatively out of the human situation."

Seeing a bland environment as a stimulant for creativity for such a giant made my life in a mediocre suburb of Los Angeles more bearable.

Finally here are my favourite quotes from Gould's 1964 essay "Advice to a Graduation", where he creates gangly, beautifully constructed explanations of the relationship of imagination, perception, craft and art in the quest of the artist and art teacher. The essay is one of the best ways I've stumbled upon to help get out of the rut as an artist and see beyond one's own nose.

"You should never cease to be aware that all aspects of the learning you have acquired, and will acquire, are possible because of their relationship with negation – with that which is not, or which appears not to be."

"When people who practice an art like music become captives of those positive assumptions of system, <...> and when they become disrespectful of the immensity of negation compared to system – then they put themselves out of reach of that replenishment of invention upon which creative ideas depend, because invention is, in fact, a cautious dipping into the negation that lies outside system from a position firmly ensconced in system."

"What [imagination] can do is to serve as a sort of no man's land between that foreground of system and dogma, of positive action, for which you have been trained, and that vast background of immense possibility, of negation, which you must constantly examine, and to which you must never forget to pay homage as the source from which all creative ideas come.”

Gould's advice to graduating musicians, which applies to all artists who have craft as a necessary constituent of their art, as concert pianists and representational artists do. Reading it two years ago overwhelmed me because I knew Gould's musical recordings, but was not aware of his ideas on art and creativity, which he defines here. I find his definitions both inspiring and alarming, because according to these, very few artists can consider themselves as fulfilling their role, I definitely am not among those who do. Gould, on the other hand, fulfills this role perfectly, and his recordings are an illustration of his written ideas in action.

* * *